Hello everybody,

We’re back with updates from the Foothill Racing Team! While we dive deeper into the design and fabrication stages, our subteams continue to work together to make strong developments to the FR-02. With structural analyses for running the engine, the car is one step closer to hitting the track! Let’s dive in and understand the team’s progress.

Chassis

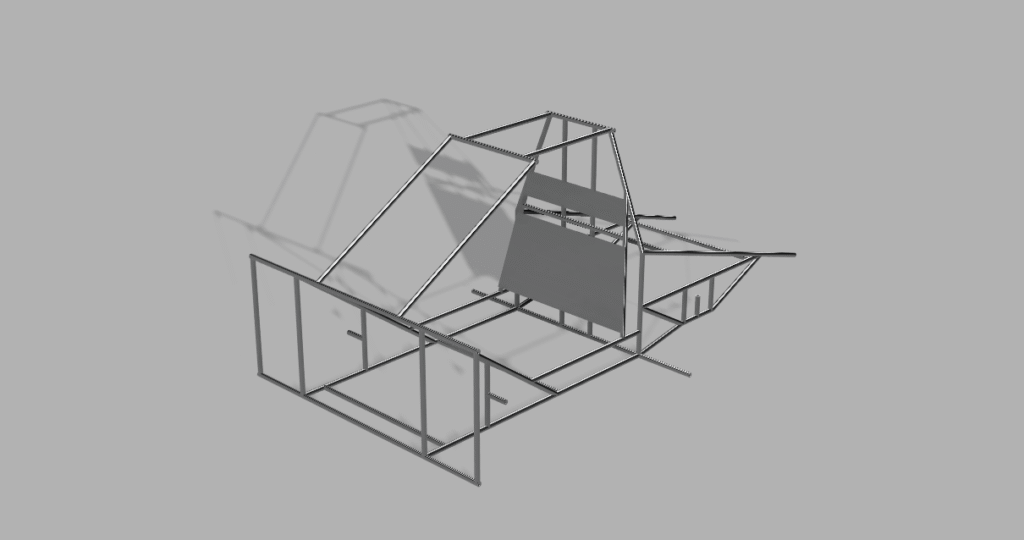

The chassis team has taken important steps to finalize the frame of the FR-02. We’re nearing the completion of the frame design; attention is now turning to the steering system and rear axle development.

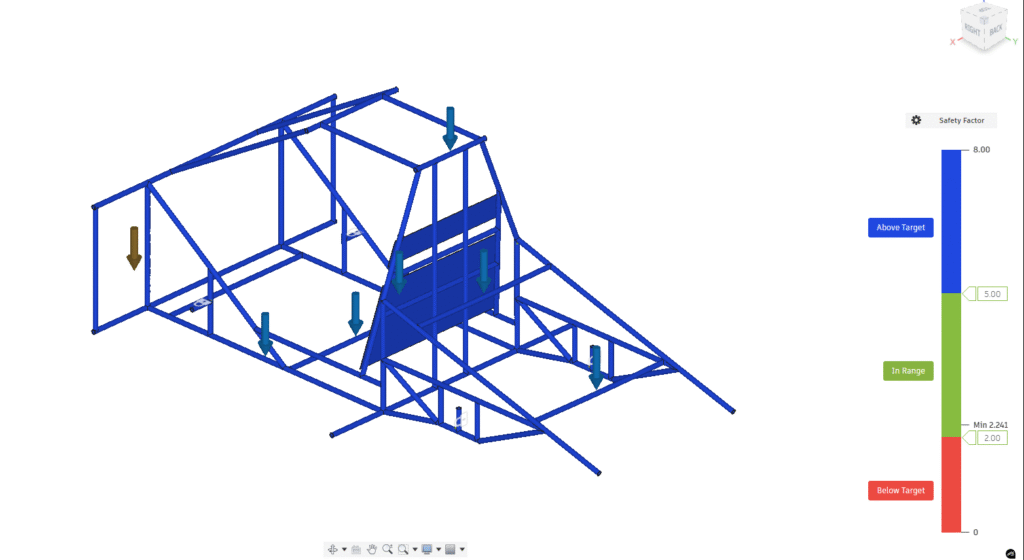

To calculate the frame’s strength during the competition, we used Finite Element Analysis (FEA) to identify weak points or areas of stress. Our results rendered a minimum safety factor of 2.241. In other words, the weakest areas of the FR-02 can withstand approximately twice the predicted load. With strong results, the chassis team is working to strengthen the frame and prepare to adjust potential weaknesses caused by welding, factors that change the metal’s overall strength and temper. The main goal is to reduce the strain on the tubular aluminum in order to ensure durability and maximum performance.

We’re also excited to announce our new sponsors! Bystronic, which will assist us in supplying and manufacturing the aluminum tubing, and Bay Area Composites are aimed at assisting in fabricating the FR-02’s aerodynamic body.

Model of the FR-02 Chassis Structure and FEA (Finite Element Analysis) results showing stress distribution across the frame.

Powertrain

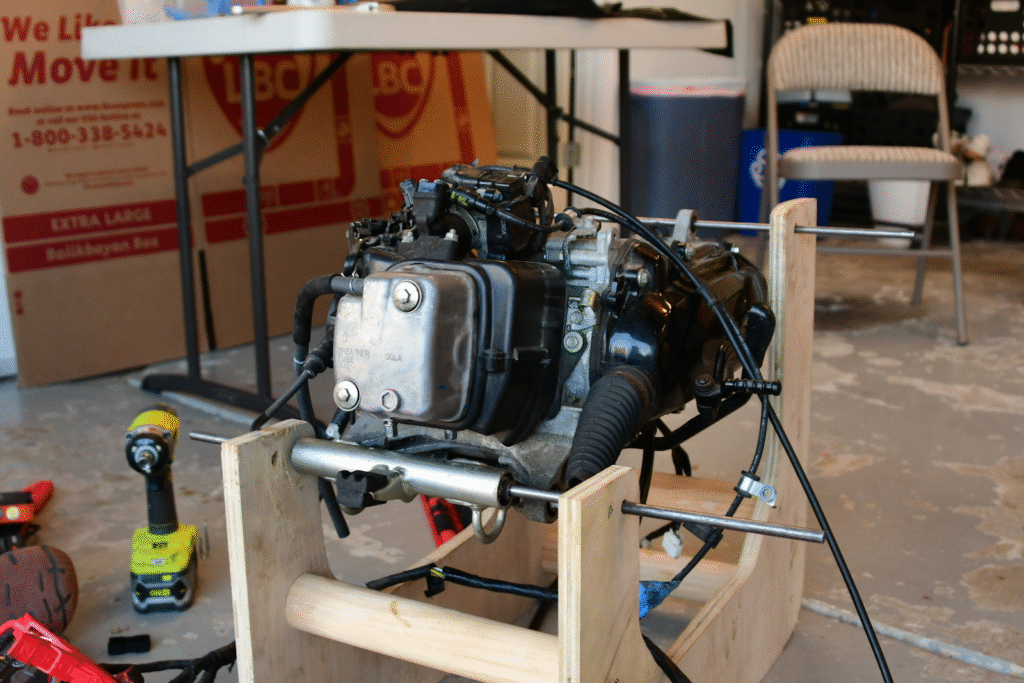

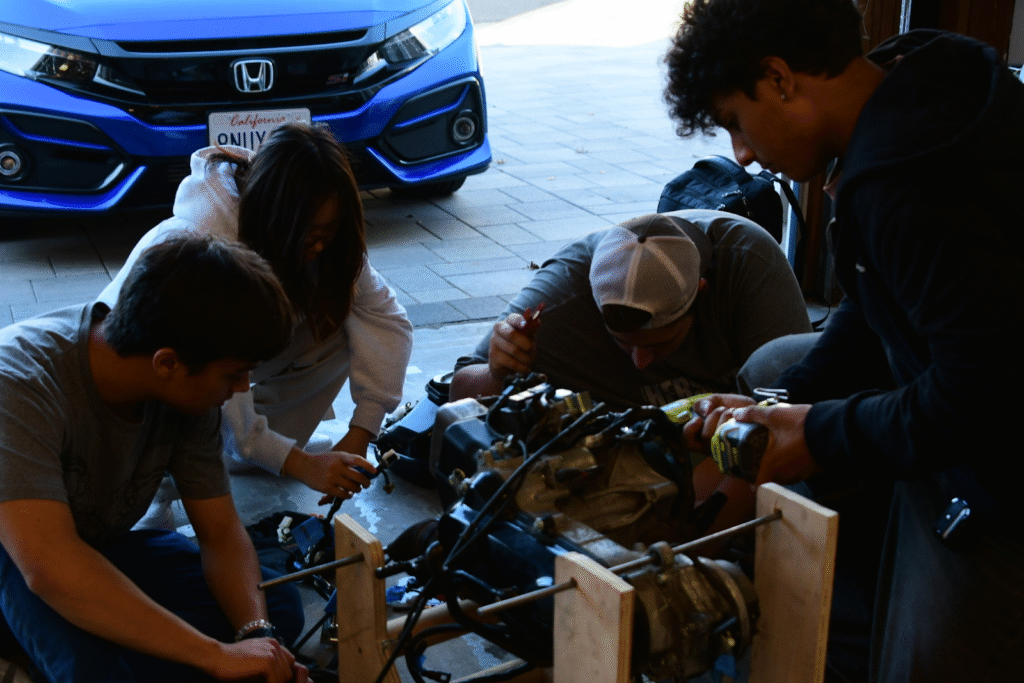

Since our last update, the powertrain team has made great progress. Our newly built custom engine stand ensures that we can safely run tests on the engine, which is now up and running—an important milestone for the Foothill Racing Team!

At the moment, we’re finding and solving small performance issues and aim to simplify the engine’s electronic systems to make it more secure and reliable for the Shell Eco-marathon. Every step brings us closer to producing a fully operational powertrain, which would be ready for chassis integration.

The Honda Metropolitan engine was mounted on our custom-built testing stand, and the powertrain team members ran diagnostics and made adjustments during initial engine testing.

Electronics

The electronics team has continued to refine its different systems. The chassis team’s completion and finalized engine creation tie directly to the electronics team’s system refining. While the car remains under construction, limited physical elements are available for full-scale testing.

Valuable groundwork (mentioned in the last post), such as test bed experimentation and validating components, has gained more impact. Numerous internal issues have been fixed, and the team can continue forward in both an efficient and creative manner as integration continues. We’re prepping the adapted systems for the evolving car design when certain components are available.

That’s all for this blog post! Just as the readers, we are excited to transform our hard work into palpable progress. The Foothill Racing Team will continue to have meetings, collaborate with sponsors and local partners, and hold subteam check-ins. We’re always on the lookout for new sponsors. If you have any questions, feel free to send an email, reach out to us in-person, or follow us online!

See you next time,

Harini Solaimalai

Foothill Racing Team