Hi everyone,

We’re back with another update from the Foothill Racing Team. Over the past few weeks, the subteams have been making important steps on our FR-02 car. From frame design to breaking apart the engine, the car has begun to take shape! Let’s analyze the progress so far.

Chassis

The chassis team has finalized the body design of the FR-02, which can be seen in the attached images. To evaluate its aerodynamics, we used CFD (Computational Fluid Dynamics) analysis. This allowed us to calculate a drag coefficient slightly above 0.2, a low figure, which determines how aerodynamic the car is. While the possibility of reducing the CFD further does remain, doing so would be unnecessarily complex for the design. The drag is a less important factor due to Shell Eco-marathon vehicles operating at relatively slow speeds. With this balance, the car has an effective, manageable, and simple structural design.

On the structural side, the main frame has been designed, though the engine and wheel mounts are being finalized. After these steps are completed, FEA (Finite Element Analysis) will be performed to evaluate the frame’s strength towards different forces that it will be exposed to during the competition.

For materials, we plan to use 6061 aluminum alloy circular tubing with a 0.75-inch outer diameter and 0.125-inch thickness. Aluminum is lighter in comparison to steel and provides an excellent balance between strength and weight. The car will run at low speeds during the competition, so the added strength of steel would not be necessary. As mentioned above, the chassis team is selecting wheels and tires to optimize for handling and performance.

FR-02 Digital Frame Model

Powertrain

The powertrain team has transitioned from planning to hands-on work. Over the past month, we purchased a Honda Metropolitan moped, the engine supply for FR-02. Which has pictures attached below. After hours of patience and detailed documentation, the team has successfully disassembled the moped and extracted the motor. With the engine fully separated, our next steps are bench testing to determine performance, efficiency, and beneficial modifications for the Shell Eco-marathon.

Honda Metropolitan Moped (Engine source for FR-02)

Electronics

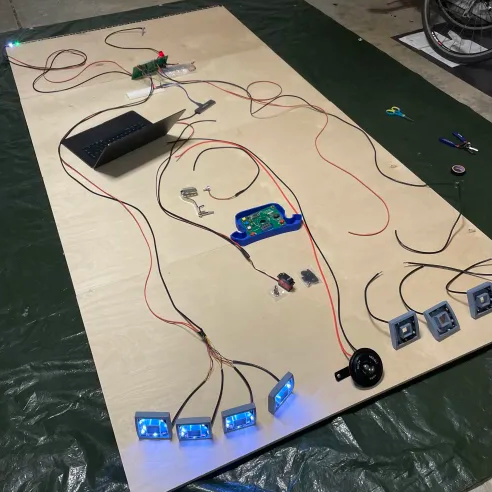

The electronics team has been working to confirm that FR-02’s systems work smoothly and reliably. First, we plan on developing everything on a test bed, a smaller version of the car’s electrical system. This allows them to create a proof of concept before the entire installation, which is critical for solving issues that arise early on, saving valuable time during later stages.

By August 20, the time had completed the first iteration of the control code after testing each electronic component individually. Then, we shifted our focus to building custom carpentry setups to resemble real car parts in order to have a realistic testing environment. These parts included a steering wheel to model the actual steering column, including wires throughout the base and connecting to the PCB (Printed Circuit Board) mounted onto a plexiglass windshield mount designed for testing the wiper system. Also, a windshield wiper prototype was created by attaching a rear car wiper to a wooden dowel, then we used epoxy glue to attach it to a servo motor to model a lifelike motion against the plexiglass. Lastly, our team built a brake pedal housing that mimics the car’s braking system.

Each setup reflects the subteam’s step-by-step ideology: research to schematic design, then CAD, PCB manufacturing, and real-world testing. By refining designs with test beds, the electronics team establishes a clear process of turning theoretical plans into functional systems.

Steering Wheel Podium PCB and Electronics Test Bed.

Wind Shield Wiper and Mount

That’s all for this update! Thanks for reading, and stay tuned for more progress from the Foothill Racing Team. In the past weeks, we have held multiple racing meetings and are always on the look out for more sponsors. If you have any questions, feel free to contact us at and look out for new blog post notifications!

Thanks,

Harini Solaimalai