Hi everyone,

Summer’s just rolled around, so it’s time for the first engineering blog post and update from Foothill Racing’s technical lead, Brandon.

Firstly, I’d like to thank the Gene Haas Foundation, our diamond level sponsor, for their support for our project. You can find out how to support our Shell Eco-marathon project by clicking on the Sponsor button at the top of this page.

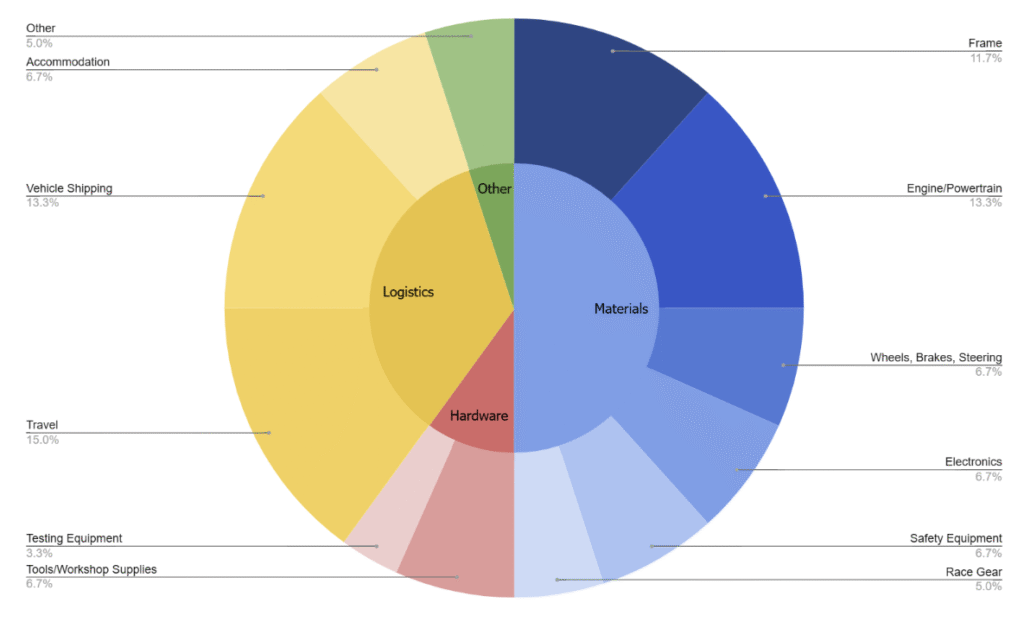

Now, an update on our budget for our car, the FR-02, for 2025-2026. We’ve created a budget breakdown for the project that can be seen here:

Please note that this is a preliminary budget estimate that is likely to fluctuate over time.

As for the engineering side of things, let me give you a breakdown of some important decisions we’ve made regarding the design of the car.

Powertrain:

We were initially thinking of using a parallel hybrid system on our car. This system is similar to what many road-going hybrid cars, such as the Toyota Prius today use. Simply put, there is both an internal combustion engine and an electric motor that both power the wheels of a car. When the car slows down, the electric motor can act as a generator to convert energy that would be lost through braking to electricity, which can then be used, increasing efficiency.

We decided not to use this system. Why, despite the potential efficiency gains? The reason is that Shell’s rules state that we aren’t allowed to use batteries, but instead larger, heavier supercapacitors. The charge of these supercapacitors must also be the same at the beginning and at the end of each efficiency run, losing out on a large chunk of the potential gain in efficiency.

So, because of the increased complexity and weight that comes with a hybrid system, as well as the negations in many of its advantages in this competition, we decided not to use one.

We are also considering our choice of ICE engine, between diesel and gasoline. We currently possess a diesel engine, but more time is needed to determine which would increase our efficiency the most.

Chassis:

We have decided that the FR-02 will use a tubular space frame chassis with outer body panels, instead of a monocoque design.

A monocoque is a type of vehicle chassis where there is no distinct frame, but instead the entire body of the vehicle acts to bear the loads of the car.

In a space frame chassis, there is an internal truss network inside the car that carries the loads of the car.

Although monocoques are generally lighter than space frames, we decided to use a space frame because it is significantly simpler and more cost-efficient than a monocoque. A monocoque would require much more time and money to design and build.

Our space frame will likely be constructed out of aluminum tubing. However, if budget allows, we will instead be using carbon fiber tubing, which has a much higher strength-to-weight ratio, allowing for a lighter car.

Electronics:

Though it may depend on what kind of engine we use, we are currently planning to have a computer controlled throttle-by-wire system to control the throttle of the engine. In a throttle-by-wire system, there is no direct connection from the accelerator pedal to the engine; instead, signals are sent electronically. We are planning this so we can more precisely control the output of the engine, with the car’s computer also adjusting the throttle to maximize efficiency. This would reduce driver error, such as applying too much throttle, maximizing our efficiency.

Thank you for reading this engineering blog post.

Once again, I’d like to thank our diamond level sponsor the Gene Haas Foundation.

We’d greatly appreciate your support. If you have any questions or want to get involved, contact us.

Brandon Kong

Will I be able to find this at the club fair in August?

Yes, we’ll be there!